Life-Cycle Cost Analysis & Its Role in Value Engineering

When starting a new construction project, every building owner’s goal is to maximize the value of their facility. During the value engineering process, an owner and their project team look for ways to do just that.

But sometimes, value engineering focuses too much on reducing the short-term costs of the project, and not enough on the impact of the long-term costs. While cutting short-term costs makes the building less expensive to build, it could end up costing more throughout the lifespan of the building.

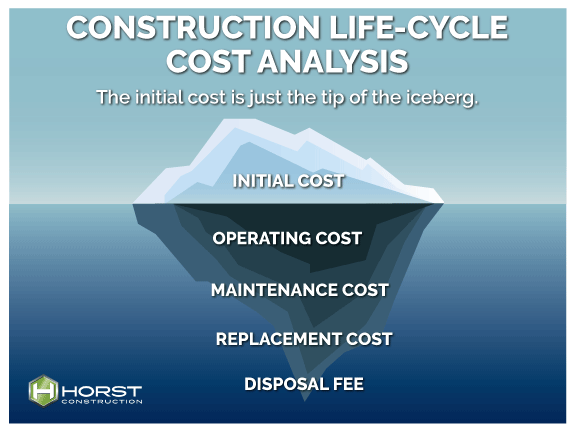

If maximizing the value of your building is your goal, you’ll have to account for what each item will cost from the day it’s purchased to the day you dispose of it. That’s where life-cycle cost analysis comes in.

Life-Cycle Cost Analysis Definition

Life-cycle cost analysis is the process during which the project team assesses the cost of a building, building material, or piece of equipment throughout its entire useful life.

It not only focuses on the more obvious acquisition and construction costs, but also on how much it will cost to operate and maintain. In other words, life-cycle cost analysis is looking at the total cost of ownership for your building or a specific item.

Life-Cycle Cost Analysis’s Role in Value Engineering

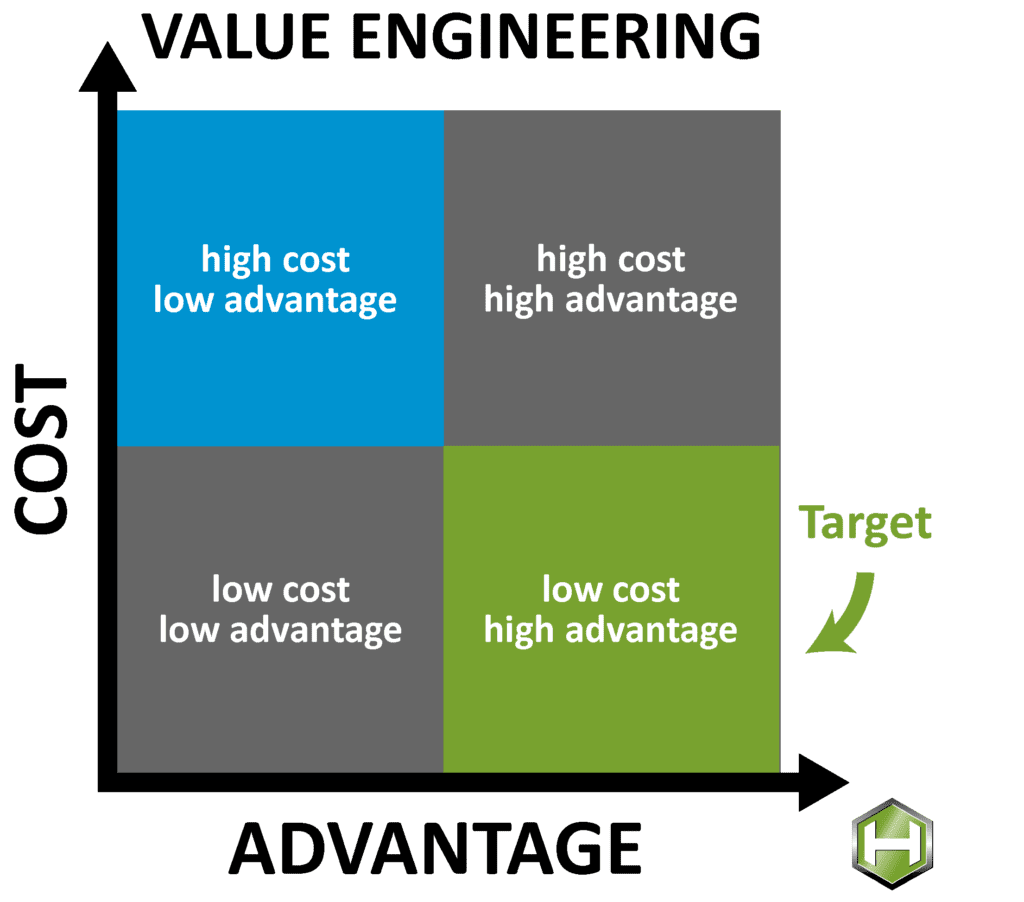

Conducting a life-cycle cost analysis can be an extremely important exercise when it comes to value engineering. By looking at the project from a big-picture perspective, you’re able to determine what options offer the best value in the short term and long term.

Conducting a life-cycle cost analysis can be an extremely important exercise when it comes to value engineering. By looking at the project from a big-picture perspective, you’re able to determine what options offer the best value in the short term and long term.

Value engineering isn’t just about reducing the overall cost of the project. Value engineering is about optimizing the value of the project and making the most out of your money so you have a long-term investment that will suit the financial goals of your business.

It’s important that you partner with a construction team that not only offers creative suggestions to value engineer the project but also clearly explains the suggestions, allowing the owner to decide for himself or herself.

For more on value engineering, check out this article.

Initial Cost

The initial costs include the purchasing price and installation or construction. These are the upfront costs associated with the building material or the equipment you choose. They’re also the costs that tend to have the most influence on purchasing decisions because they have the biggest impact on the project’s budget at the time of the decision.

However, initial costs are just the tip of the iceberg. Many additional costs lie below the surface and need to be considered when evaluating the true cost and value of an item.

Opting for the option that has the least expensive initial price while ignoring the long-term costs could end up being more expensive. For example, an item that is $3,000 but needs to be replaced in five years will be less valuable than a comparable item that is $5,000 that lasts ten years.

That said, overextending your construction project’s budget for modest savings in the long term isn’t be in your best interest either. Your project team should work hard to understand your budget and present you with the options and explanations that clearly outline the full life-cycle cost of the item. That way you can make an informed decision that’s best for your project.

Operating Costs

One of the first post-construction costs you’ll likely run into is the operating costs. These include everything from fuel to run the equipment to regular cleaning or upkeep. These costs are more of an estimate, as they tend to fluctuate from year to year or month to month. However, these estimates can provide valuable insight into your long-term costs.

When it comes to equipment, more efficient items can cost less to operate. However, they tend to have enhanced technology which is accompanied by a higher price tag. For finishes and other construction materials, less expensive options may require more frequent maintenance or cleaning, while sturdier and higher-value items can handle more use.

When deciding between options, don’t overlook the operating costs. While they may not seem incredibly significant, keep in mind these costs will be recurring for the entire lifespan of the item. They can quickly add up to a significant sum.

Maintenance Costs

Another aspect you need to consider is the maintenance factor associated with the item.

How easy is it to find maintenance technicians that are qualified to diagnose and work on your equipment? If new parts are needed, will they be easy to find, or will they have to be purchased from abroad or custom-made? What are the warranties like? Will the manufacturer stand behind their item, or will you be forced to pay a big bill if something with the equipment goes wrong?

These questions can help guide you when you’re making the decision for your specific product. While we hope all equipment is built to last and will operate for years with no issues, that’s simply not always the case. Should something go wrong, affordable maintenance can increase the overall value of the item, even if that item is slightly more expensive.

Replacement Costs

Nothing lasts forever, and eventually, specific portions of the building or specific equipment will have to be replaced. All costs associated with replacing that item need to be factored into the life-cycle cost. This can include physically removing or uninstalling the item, the acquisition of a new item, and the installation of the new item.

While one can’t predict with 100% accuracy what the market will be like for an item once it reaches the end of its useful life, considering the possibilities is important. Material shortages could increase the cost beyond inflation, or advances in technology could make it even more affordable.

Either way, considering the frequency and cost of replacement is going to factor into the overall value of your project in a big way. For example, it might be tempting to swap out your carpet for a cheaper option while in the value engineering phase, but if you have to replace it in just a few years, the savings may not be justified.

Disposal Fee

Life-cycle cost analysis considers the cost of a product throughout its entire life. This includes when the product reaches the end of its useful life and needs to be disposed of. This can be an easy cost to overlook, as so much of what we dispose of on a day-to-day basis can be done relatively simply and for free. However, when it comes to certain building materials or equipment, an additional cost may be required.

If your item contains hazardous chemicals, it may need to be disposed of or recycled in a specific manner, which could require an additional fee. However, some items may have a positive resale value, allowing you to cash in by passing it on to a second-hand buyer or a salvager.

While it may not be the first cost that comes to mind when choosing building materials, finishes, and equipment for your new building, the disposal of that item is a very real cost that should be included in the life-cost analysis.

How to Maximize Your Project’s Value with Life-Cycle Cost Analysis

Whether you’re renovating or building a new structure, a construction project can be a large investment. The choices you make during the planning process have the potential to impact the building and your budget for years to come.

Taking a long-term look at your building materials and equipment with a life-cycle cost analysis can help ensure you’re making the best decisions for your present and future self.

While predicting the future is impossible, working with a construction company that can look at a life-cycle cost analysis through the lens of decades of industry experience can make this process easier.

At Horst Construction, we respect your budget and resources and will do all we can to enhance your project’s value for the long term while still meeting your immediate budgeting needs. By providing meticulous details explaining each item’s impact on your building’s life cycle and the project’s cost, Horst Construction strives to bring our clients a “no surprises” construction experience.

Posted September 09, 2021