The True Meaning of Value Engineering

You’ve worked with your design team to draw up your dream building. You’re getting your employees, residents, customers, or congregation excited about what the new building will bring. You request bids from a group of general contractors, eager to make this gorgeous design a reality.

But the bids come back way higher than you expected.

Is now the time to mercilessly “value engineer” your project to get the cost down?

Not necessarily.

When someone says “value engineering” our minds immediately go to a process that reduces the cost of the project by cutting out portions or reducing the quality of materials and methods being used.

However, that is not necessarily what value engineering should be.

WHAT IS VALUE ENGINEERING?

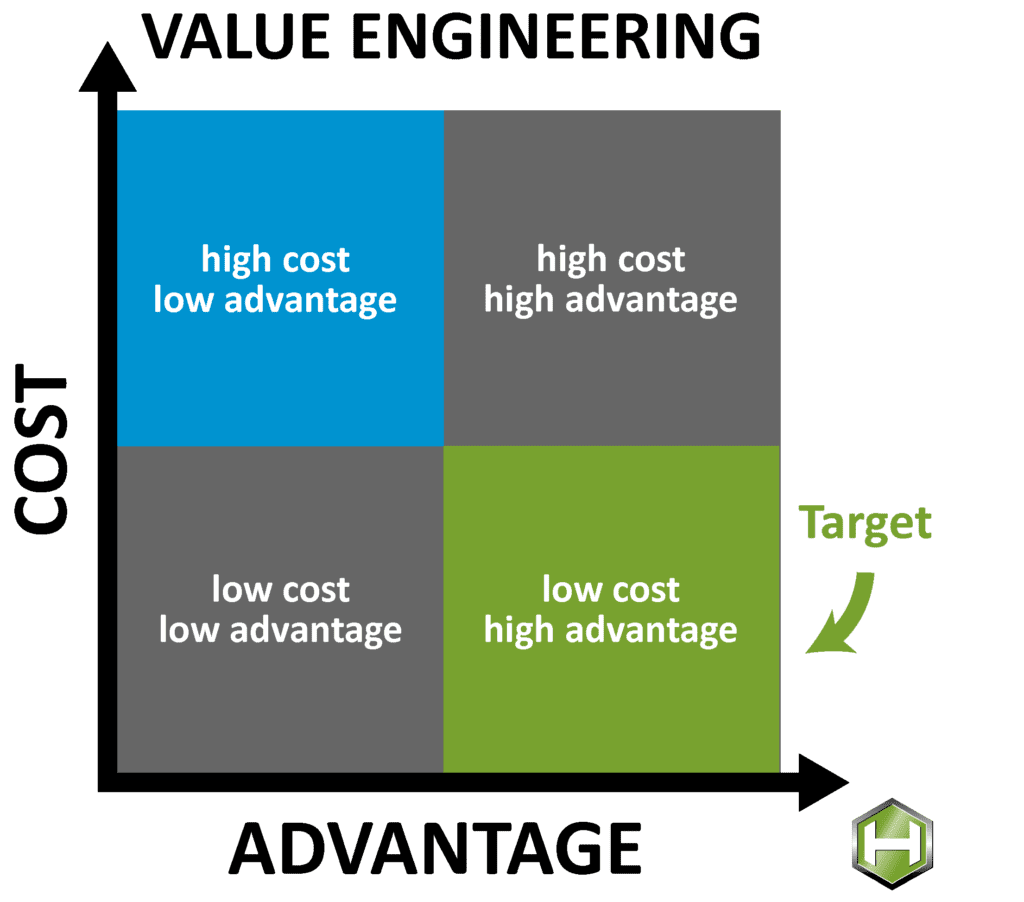

In the construction industry, the definition of value engineering (VE) is the method that your project team employs to improve the value of your project by examining the function of each item or element and its associated cost. By weighing the function-to-cost ratio, your team can make suggestions for alternate construction methods, designs, or materials that improve the value of the project.

In the construction industry, the definition of value engineering (VE) is the method that your project team employs to improve the value of your project by examining the function of each item or element and its associated cost. By weighing the function-to-cost ratio, your team can make suggestions for alternate construction methods, designs, or materials that improve the value of the project.

It’s important to note that improving the value of your project does not mean cutting costs. It means optimizing the elements of the project through an analysis of all factors–cost, upkeep, wear-and-tear, aesthetic value, etc.

To truly provide advantageous value engineering, your construction and design team need to first understand the project as a whole and your vision and goals for the project. Every project is different, as is every client’s definition of value.

DEFINING “VALUE” FOR YOUR PROJECT

Something that has a favorable ratio of costs to benefits is considered a good value. While costs may seem easy to define – how much they cost upfront – there’s a little more to it. To really understand the value, you need to dig deeper. How long will those materials last? What type of maintenance will they need? Will they work more efficiently and cost less to operate? The best place to start is to ask yourself what is/are the most important part(s) of the project, and what do you want the project to achieve? Once you’ve identified them, share them with your value engineering team, and they’ll get back to you with a list of suggestions that respect your goals and enhance your project to provide the best possible value that meets your budget. This approach is one of value enhancement for your individual project – rather than sweeping cost-cutting measures that may not be the best fit for your needs or goals. A good value engineering team will take all things into consideration and find you the best quality options at the lowest available cost.

When evaluating these suggestions, keep these three main criteria in mind: cost reduction, added quality, and life cycle/maintenance.

Cost Reduction

Cost reduction is what drives many value engineering processes. Your value engineering team will bring ideas of less costly materials or systems to your project for your consideration. Whether that’s finding a similar fixture that costs less or alternating an unnecessary feature, these suggestions can bring value to your project.

However, without the next criteria, value engineering would just be called cost-cutting. Added quality ensures that the cost cuts made do not diminish the value of the project.

Quality

Before making any decisions on your value engineering options, you need to consider quality. Quality can have a lot of different meanings. Quality of the environment you’re creating. Quality of the products that make up that environment. Quality of the team you’re choosing to create that environment.

While some equipment or design elements may have a higher cost, they could be justified by the quality that they bring. Higher-cost items and elements may allow you to charge more for your services. They may have a positive impact on the productivity or happiness of the people who will use the space. A quality product could have more overall value than a low-cost product.

Life Cycle/Maintenance

Similar to quality, it’s important to consider the long-term implications of these value engineering decisions. While a low-cost flooring may seem like the most valuable option initially, if you need to replace it twice as frequently as a higher-cost flooring, it could end up costing you more money in the long run.

However, if saving that extra money upfront is the difference between getting your project off the ground or having it stall out in design, then making that decision may very well be the best option.

WHEN SHOULD VALUE ENGINEERING TAKE PLACE?

At a high level, there are three main stages of a construction project: project planning, design, and construction. As an owner, you can call for value engineering services at any time throughout the construction process. However, the pros and cons of making changes vary from stage to stage.

Value Engineering During Project Planning

In most cases, the planning stage of your project is the best time to value engineer. The cost to implement these changes will be the lowest, and it will have the least effect on the project’s schedule.

At this stage, your value engineering team will take a close look at the facility and work with you to flush out your vision and objectives for the project. Armed with this information, they’ll be able to offer you alternative solutions that will fit your project. Then, they’ll seamlessly work them into the project plan.

While this requires more preparation upfront, it will save you from costly change orders that can push back your project’s schedule down the road.

Value Engineering During the Design Phase

For most traditional projects, value engineering happens during the design phase. The owner works with a design team to develop construction documents, and those documents are then used by contractors to develop cost estimates. When those estimates come back too high, the project team goes back to the drawing board (literally) and starts looking for ways they can save you some money.

However, it’s worth reiterating that value engineering shouldn’t just be about lowering construction costs. The value engineering team needs to look at costs long-term and the value of the project as a whole and make suggestions that align with the owner’s objectives.

One of the downsides of doing most of your value engineering during the design phase is that you can incur redesign costs.

Value Engineering During the Construction Phase

Just because boots are on the ground and construction is underway doesn’t mean your project team should stop looking critically at the project. Value engineering can continue as work is put in place with suggestions from contractors through value engineering change orders.

However, because construction is already underway, changes to the plans can be costly and may alter the project schedule. All value engineering suggestions during this phase need to be looked at critically to understand the full impact the change will have on the project.

That’s why it’s important to partner with a construction firm that’s committed to doing the right thing and being good stewards of your resources. At Horst Construction, we’ll be an engaged team member from the second we become involved throughout the entire process. We’ll never stop looking for ways to add value to your project.

This blog was originally published in August of 2015, but was updated and republished March 18, 2020.

Posted March 18, 2020